The Titanium Revolution: Unveiling the Strength, Versatility, and Sustainability of a Metal Marvel

In the world of metals, few stand as tall and shine as bright as titanium. This remarkable element has become synonymous with strength, versatility, and innovation across various industries. From aerospace, automotive, motorsports, to medical advancements, titanium’s unique properties have propelled it into the limelight, making it an indispensable material in the modern world. The global titanium market was valued at $28 billion in 2022. This market is projected to expand at a significant rate to reach an estimated size of nearly $52 billion by 2030. In this blog post, we delve into the fascinating world of titanium, exploring its properties, applications, and the crucial potential for increasing global sustainability.

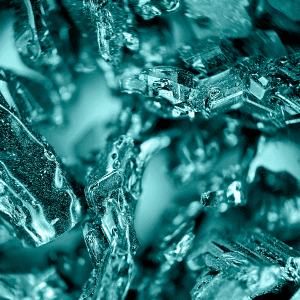

Exploring Titanium's Properties and Sources

Titanium, with its atomic number 22 and symbol Ti, is derived from the mineral ilmenite, which primarily consists of iron and titanium dioxide. Rutile and anatase are other minerals that contribute to the titanium production process. However, ilmenite remains the primary source, constituting about 95% of the titanium minerals extracted globally. It is a transition metal known for its exceptional strength-to-weight ratio. It boasts a tensile strength comparable to steel but at only 45% of the weight. This attribute makes titanium a preferred choice in industries where lightweight, yet robust materials are essential.

Global Production and Supply Chain of Titanium

The production of titanium is a complex process that involves several stages, from extraction to refinement. The main titanium-producing countries include China, Japan, Russia, Kazakhstan, and the United States. These nations possess extensive titanium reserves and contribute significantly to the global supply chain. China, as the world’s leading producer, plays a pivotal role in the titanium market. The country’s dominance is attributed to its vast ilmenite reserves and advanced processing capabilities. While Japan does not have significant natural deposits of titanium minerals like ilmenite, rutile, or anatase, it relies on global trade and partnerships to secure the necessary raw materials. Russia, with its rich ilmenite deposits in the Ural Mountains, is another major player, ensuring a stable supply of titanium to meet global demands. China produces the highest amount of titanium in the world at 120,000 metric tons in 2021, twice as much as Japan (35,000) and Russia (27,000) combined.

Titanium's Environmental Impact and Sustainability Efforts

The production of titanium involves energy-intensive processes, primarily the extraction of titanium dioxide from its mineral ores, such as ilmenite or rutile. This extraction process, known as the Kroll process, requires high temperatures and consumes substantial amounts of energy, often derived from fossil fuels. Consequently, the production and use of titanium contribute significantly to global carbon dioxide emissions (CO2e). The production of 1 ton Titanium can contribute to as much as 17 tons CO2e! Emerging technologies, including Hydrogen-based Reduction, Electrochemical Processes, and Advanced Smelting Technologies, are dedicated to minimizing CO2e emissions. Each of these innovations is directed toward employing cleaner production methods and reducing the overall energy requirements.

The Mechanical Marvel of Titanium

Titanium’s mechanical properties make it stand out among metals. Notably, titanium boasts high tensile strength, excellent corrosion resistance, and a low density. These characteristics make it an indispensable material for applications where a combination of strength, durability, and lightweight properties is paramount. With a density of approximately 4.5 g/cm³, titanium is about 40% lighter than steel. Despite its low density, titanium boasts impressive strength, comparable to that of steel. This combination of low weight and high strength makes titanium an invaluable material in applications where weight savings are critical, such as aerospace, automotive, and motorsport engineering. Furthermore, titanium exhibits exceptional corrosion resistance, especially in environments where other metals may succumb to corrosion. This property, coupled with its biocompatibility, renders titanium ideal for medical implants, such as hip replacements and dental implants. The metal’s inert nature minimizes the risk of rejection by the body, making it a safe and reliable choice for various medical applications.

Titanium: An Industry Game Changer

According to the International Titanium Association, the aerospace industry consumes approximately 40% of the global titanium production. Titanium constitutes a significant portion of the structural materials in modern commercial and military aircraft.

Aerospace Applications

- Aircraft Components:

- Airframes:Titanium’s high strength-to-weight ratio is crucial in constructing durable and lightweight airframes. Approximately 20% of the weight of advanced commercial aircraft is made of titanium.

- Engine Components:Titanium alloys are used in the manufacturing of critical engine components such as turbine blades and discs, ensuring high-temperature resistance and structural integrity.

- Spacecraft and Satellites:

- Spacecraft Structures:Titanium is used in the construction of spacecraft structures due to its lightweight nature and ability to withstand the harsh conditions of space.

- Satellite Components:Titanium’s corrosion resistance makes it suitable for components exposed to the vacuum of space, ensuring the longevity of satellite structures.

Automotive / Motorsport Applications:

- Vehicle Components:

- Chassis and Frames:Titanium’s high strength-to-weight ratio proves crucial in supporting robust yet lightweight chassis and frames, enhancing overall vehicle performance. Studies indicate a weight reduction of up to 40% compared to traditional materials, contributing to improved fuel efficiency.

- Engine Components:Titanium alloys play a key role in crafting critical engine components, such as valves and connecting rods, ensuring resilience under extreme racing conditions. Titanium valves, for instance, can withstand temperatures exceeding 1,600°C, outperforming traditional materials.

Medical Applications:

- Dental Implants:

- Titanium is widely used for dental implants due to its biocompatibility and ability to fuse with bone, a process known as osseointegration.

- Approximately 95% of dental implants are made of titanium or titanium alloys.

- Orthopedic Implants:

- Titanium is utilized in orthopedic implants, including hip and knee replacements, spinal implants, and bone plates.

- Titanium’s corrosion resistance and strength make it an ideal material for load-bearing implants.

Titanium's Role in Sustainability and Recycling

Titanium’s exceptional durability and longevity play a crucial role in promoting sustainability across various industries. This robustness translates into a prolonged lifespan for products incorporating titanium, contributing significantly to sustainability efforts.

In aerospace, where weight and strength are paramount, titanium’s durability ensures the longevity of components outlined above. The extended life cycle of these titanium-based aerospace materials reduces the frequency of replacements, resulting in less material consumption and waste over time. This not only positively impacts the economic efficiency of the aerospace industry but also aligns with environmental goals by minimizing the carbon footprint associated with manufacturing and disposal of materials.

In the medical field, the longevity of titanium implants is particularly noteworthy. The remarkable fact that the average lifespan of titanium implants can exceed 20 years is a testament to the metal’s ability to withstand the harsh conditions within the human body while maintaining structural integrity. This longevity significantly reduces the need for frequent replacements, thereby minimizing medical waste and the environmental impact associated with the production and disposal of medical devices.

Unlike some materials that degrade during recycling, titanium stands out for its enduring characteristics. This means that the metal can be recycled multiple times without a significant decline in its structural or functional qualities. This quality of endless recyclability is significant for sustainability efforts. It reduces the need for extracting new titanium resources, thereby contributing to a decrease in the environmental impact associated with traditional mining processes. Mining activities often lead to deforestation, habitat destruction, soil erosion, and other adverse effects. By relying on recycled titanium, there is a substantial reduction in the demand for new mining, resulting in minimized environmental consequences.

With a recycling rate of approximately 95%, titanium showcases its potential as a sustainable material. This high recycling rate implies that a large majority of titanium used in various applications is effectively collected and recycled, contributing to a more environmentally friendly approach. Overall, the enduring properties of titanium and its high recycling rate position it as a valuable resource in the pursuit of sustainable and eco-friendly materials.

Addressing Environmental Concerns and Future Directions

To address the environmental impact of titanium on CO2 emissions, there is a growing need for sustainable practices and innovations in the titanium production process. One approach is to invest in research and development to identify alternative methods that are more energy-efficient and environmentally friendly. Additionally, advancements in recycling technologies can help reduce the reliance on virgin titanium production, thereby decreasing the overall carbon footprint associated with its extraction and refinement.

Efforts to minimize the negative impact of titanium on CO2 emissions should also involve the implementation of strict environmental regulations and standards within the titanium industry. Governments and international organizations can play a crucial role in setting emission targets, promoting cleaner production methods, and incentivizing the adoption of sustainable practices. Furthermore, industry stakeholders should collaborate to share best practices, promote transparency, and invest in the development of cleaner production technologies, carbon capture and storage technologies to mitigate the emissions generated during the titanium production process.

Conclusion: Balancing Progress with Environmental Responsibility

In conclusion, titanium’s dominance across various industries highlights its unparalleled strength, versatility, and sustainability. As the global titanium market surges towards a projected $52 billion by 2030, its impact on various sectors is undeniable. However, the environmental challenges associated with its production, such as energy-intensive processes and substantial carbon emissions, call for a delicate balance between its benefits and responsible use.

Titanium’s durability significantly contributes to sustainability, particularly in aerospace and medical applications, where extended life cycles reduce material consumption and waste. With an impressive recycling rate of approximately 95%, titanium showcases its potential as an eco-friendly material, minimizing the need for new mining and decreasing environmental consequences. To fully unlock titanium’s potential while addressing its environmental impact, there is a critical need for sustainable practices, innovative production methods, and stringent regulations. Balancing progress with environmental responsibility is key to ensuring that the Titanium Revolution leads to a future where titanium continues to shine without compromising the health of our planet.